- Tel: +86-731-84699028, 84699058

- Email: pfk@perfly-bio.com

Oil is an important component in feeds. As a source of feed energy, oil can not only provide energy and store energy for livestock and poultry by providing sufficient essential fatty acids, but also significantly improve feed palatability and feed efficiency.

When fatty acids in feed oil are in the process of processing and storage, some conditions, such as temperature, humid, oxygen, and light, suitable for microorganism growth and reproduction and long-term storage can make fat acids oxidated, producing toxic compounds with rancid odors, so oil also becomes bitter, which is the oxidative rancidity of the oil.

Oil oxidative rancidity is a naturally occurring process, which occurs whenever there is oxygen, water and microorganisms in the environment. At the same time, oxidative rancidity of oil is a complex process, temperature, fatty acid composition, metal ions, oxygen, light and so on are the inducement of oxidative rancidity of oil.

In production, high temperature and high humid can accelerate oxidation. Temperature affects the oxidation rate of oil and the formation of oxidation products. Lipase activity increases with the increase of temperature, so does the growth rate of microorganism, thus accelerating the rate of oil rancidity.

Some research showed that the oxidation rate of pure oil increased by two times for each 16 Celsius up when the temperature was at 21~63 Celsius. The results show that the oxidation stability of oil is sensitive to temperature change under the condition of constant oxygen supply. And now the June high temperature is high, the problems of oil oxidation should be focused on.

Oil oxidative rancidity can cause some problems:

①Palatability down affects feed intake;

②Oxidative stress can be caused;

③Oxidated oil damages muscle tissue to cause ceroid to accumulate in tissues, eventually fat turns yellow, forming yellow fat;

④ Digestion and absorption and immune function of livestock and poultry can be affected;

⑤Oxidized oil can reduce the fluidity of biofilms to destroy the integrity of membrane structure, making the normal function of biofilm and normal cell metabolism disorder. The oxidation products of rancidity oil damage several important enzyme systems in the body, such as succinic acid oxidase and cytochrome oxidase, resulting in metabolic disorder and growth retardation;

⑥Long-term ingestion of rancidity oil can reduce animal weight, causing developmental disorders, organ lesions and cancer.

Oxidized oil seriously affects animal health and damages the interests of feed mills and breeders. Nowadays, oil price stays high, so it is very important for nutritionists and formulators to choose a high-quality oil.

The microcapsule emulsified fat powder produced by Zhonglian Biotech Co., Ltd., a subsidiary of Perfly, adopts advanced technology and excellent coating materials, with maltose and oligomerized maltose as the main wall materials, which can strengthen the spleen and the stomach, and promote the digestion and absorption of nutrients. Oil is coated by sugar and casein by using microencapsulation technology and can isolate from the external environment, not easy oxidation, so it can be preserved for long time; Effectively solve the problem of easy oxidation and rancidity of feed oil.

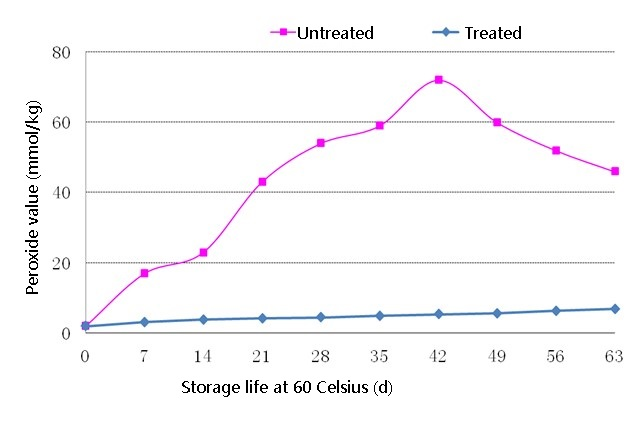

The data of emulsification microcapsule trial showed that the peroxide value of the micro-encapsulated linseed oil was much lower than that of the non-microencapsulated linseed oil, and its antioxidant capacity remained stable over time.

Figure. Antioxidant effect of microencapsulation linseed oil

The key point of oil microcapsule technology is oil encapsulation efficiency. The oil encapsulation efficiency is closely related to the formula and technologies. oil encapsulation efficiency directly affects the antioxidant property of oil.

PerPremix SNR use high-quality oil, safer and more stable. Oil is coated to isolate from the external environment, not easy to be oxidative metamorphism, especially in high temperature weather, premix and concentrated feeds with high mineral content. The stability of the products is significantly enhanced to ensure the breeding effect and reduce user complaints.

For more details, please consult biotechnology service teachers and product engineers.